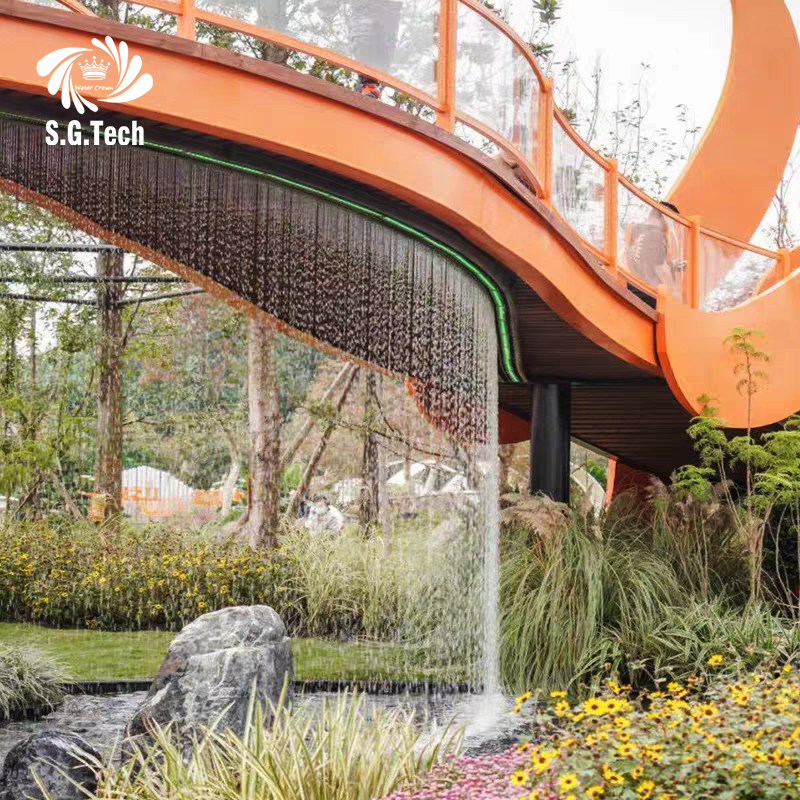

Swimming pool water curtain design balances aesthetic ambition with functional practicality, tailored to enhance recreational spaces while ensuring safety and durability. The design process begins with precise site analysis, considering pool dimensions, water chemistry (pH 7.2 7.6), and surrounding architecture. Curtains are typically positioned at pool ends or along side walls, maintaining a minimum distance of 1.5m from swim lanes to avoid obstruction. Hydraulic calculations determine optimal flow rates (15 30 m³/h) and pressures (8 20 bar) to create a visually striking curtain without generating excessive turbulence—fan nozzles with 60° spray angles are commonly used for wide coverage. Materials selection prioritizes chlorine resistance, with 316 stainless steel for fixtures, PVC coated polyester for flexible curtains, and anti algae coatings on submerged surfaces. Underwater lighting systems feature low voltage (12V DC) LED panels with RGB controls, often recessed into pool walls at 0.5m intervals for uniform illumination. Acoustic integration includes waterproof speakers (IP68) mounted behind curtains to synchronize music with water movement, while vibration dampening mounts prevent noise transfer to surrounding structures. Safety features exceed industry standards, with GFCI protected electrical components, slip resistant flooring with CoF (coefficient of friction) ≥0.6, and emergency stop buttons within 5m of the curtain. Architectural integration may involve curved curtain designs to complement infinity pools, or cascading curtains that transition into waterfalls. Compliance with local building codes is critical, including load bearing calculations (curtains can exert up to 50kg/m²), electrical bonding requirements, and wind load considerations for outdoor installations. Post installation commissioning includes flow uniformity tests (±3% variance) and water quality monitoring to ensure long term performance.