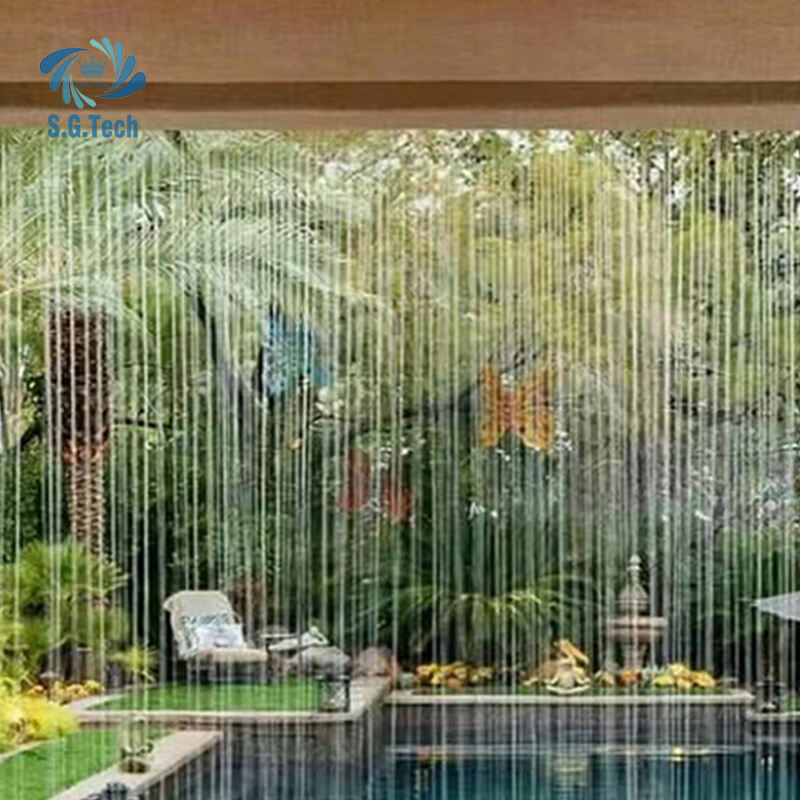

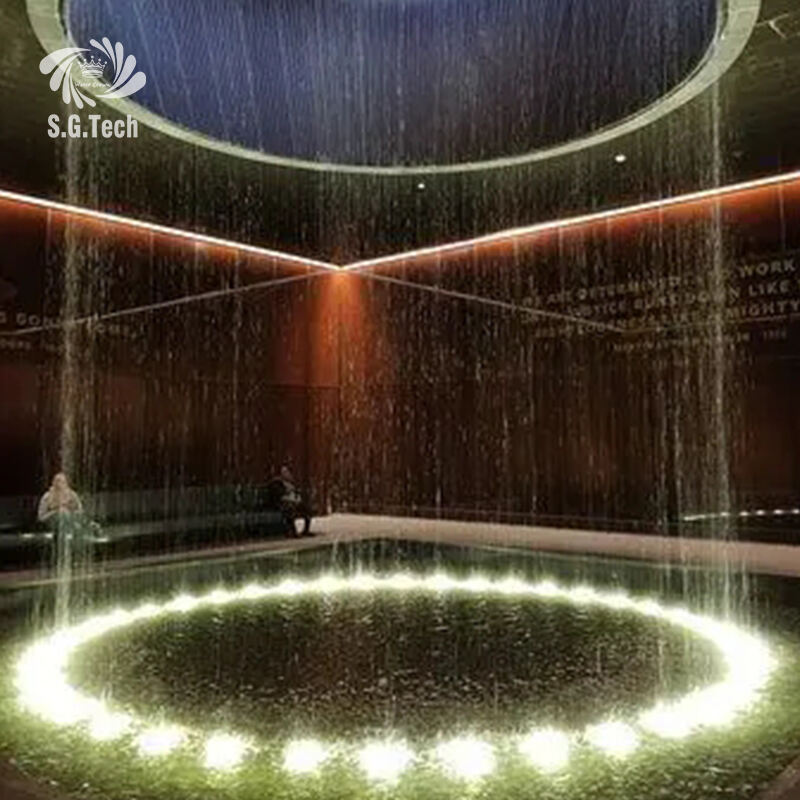

Installing a rain curtain fountain requires meticulous planning and technical expertise to ensure functionality and safety. The process begins with site assessment, including structural load analysis (fountains can exert 50 80kg/m²) and water supply pressure tests (minimum 2 bar for basic systems). Professionals use laser leveling to ensure the fountain frame is perfectly horizontal, while waterproof membranes prevent water seepage into building foundations. Pipework is typically constructed from PVC or stainless steel, with filters (5 20 micron) to prevent nozzle clogging. Electrical components, rated IP68 for waterproofing, are connected to a control panel with GFCI protection. LED lighting is often embedded in the fountain structure, requiring anti vibration mounts to withstand water movement. Commissioning involves flow rate calibration (10 50m³/h) and uniformity tests using dye injection, ensuring water sheets are seamless. Compliance with local plumbing and electrical codes is mandatory, with final inspections verifying safety features like emergency stop buttons and overflow drainage.